It is estimated that up to 60% of the cost comes from construction materials? That’s why selecting the highest quality and most cost-effective materials for your projects is crucial. One material has emerged as a game-changer – polyethylene pipes (PE). This versatile plastic material offers many advantages that have revolutionized the way we build. So, if you’re curious how PE pipe redefined modern construction, read the blog of TLD Vietnam to find out!

An Introduction to PE Pipes Versatility, Production and Advantages

PE pipe has been produced in the world since the mid-1950s. Since then, PE use and the number of applications for PE pipe have grown enormously, due to its versatility and the advantages it offers over iron, steel, and cement systems.

PE is an abbreviation for polyethylene, which is a thermoplastic material created from the polymerization of ethylene. The process for making PE pipe is called extrusion, which makes it easy to produce pipes of varying sizes. This pipe holds well under pressure, which is why it’s utilized for a variety of pressure applications (more on this later). Typically, PE pipes can be purchased in straight lengths or coils, which makes long-distance installations easier. The pipes with smaller diameters are sold in coil,s while the pipes with larger diameters are usually sold in straight lengths. Being made of plastic, PE pipes are incredibly lightweight, which is advantageous for all scales of piping projects.

Advantages of PE Pipes

Durability and Longevity

PE pipes are well known for their outstanding corrosion resistance and long service life. They effectively withstand chemicals, moisture, and microbial growth, making them ideal for industries that require durability, such as water distribution, oil and gas transport, sewage, agriculture, and geothermal systems.

With fully welded joints ensuring a leak-proof system, PE pipes can last over a century without issues like pitting, cracking, or corrosion, which commonly affect traditional piping materials.

Flexibility and Ease of Installation

One of the most significant advantages of PE pipes is their exceptional flexibility, which greatly simplifies the installation process. This flexibility reduces both labor costs and installation time by allowing the pipes to bend naturally around curves and contours without requiring additional fittings. As a result, construction becomes more efficient, particularly in areas with obstacles such as buildings, trees, or uneven terrain, where rigid pipes would require more complex planning and additional components.

Furthermore, PE pipes offer excellent adaptability on-site, making it easy to accommodate last-minute design modifications or unexpected changes in the project layout. This ability to adjust quickly without extensive reworking makes PE pipes an ideal solution for a wide range of applications, ensuring efficiency and cost-effectiveness in various construction and infrastructure projects.

Chemical Resistance

PE pipes are chemically inert, meaning they do not react with most substances, ensuring durability even when exposed to hazardous materials.

Their non-porous surfaces prevent chemical absorption or penetration, eliminating the risk of leaching into the pipe material. This makes them a preferred choice in industries handling corrosive chemicals, such as chemical processing, water and wastewater treatment, and irrigation systems.

Safer installation

In open-cut projects, PE pipes don’t require wide trenches since their joints are welded above ground rather than inside the trench, as with other systems. This eliminates the need for workers to be in trenches, making the installation process significantly safer.

Cost-Effectiveness

PE pipes provide several cost-saving benefits over materials like steel and concrete. Their lightweight and flexibility lower transportation expenses, and HDPE often has the lowest lifecycle cost among pipe materials. In many cases, it also offers the most affordable installation, as trenchless methods typically cost only 50–75% of open-cut installations. Even open-cut projects can be more economical since HDPE pipes don’t require wide trenches, with joints welded above ground rather than inside the trench, as seen with socket ring jointed systems.

Environmental Benefits

PE pipes offer several environmentally friendly benefits, making them a sustainable choice for modern construction. They are highly recyclable, with used components being collected, processed, and repurposed into new PE products, helping to minimize waste.

With a lifespan of 50 to 100 years, PE pipes require fewer replacements, reducing disruptions to ecosystems and landscapes while also lowering material consumption and the energy used in production, transportation, and installation. Additionally, their selective shutoff capabilities allow for targeted repairs or modifications, minimizing downtime and supply interruptions.

Modern Construction Applications Of PE Pipes

PE pipes are highly versatile and suitable for a wide range of industries and applications. Below are some of the most common uses of PE pipes in modern construction.

Plumbing Systems

PE pipes are widely used in residential and commercial plumbing systems due to their flexibility, making them suitable for different designs and layouts. Their corrosion resistance ensures the safe and reliable transport of potable water. Common applications include trunk water supply mains, distribution networks, and in-house plumbing. Additionally, they effectively absorb water hammers rather than transmit them, enhancing system durability.

More and more, people are beginning to recognize that water is the precious resource. Join the thousands of municipalities that protect our water and lower their costs by using HDPE, the leak-free system!

Gas Distribution

PE pipes are widely utilized in gas distribution systems because they can safely convey gas over long distances without the risk of leaks and issues related to corrosion. Their corrosion resistance and ability to withstand pressure fluctuations make them ideal for natural gas transportation for homes, businesses, and industrial facilities.

Geothermal Heating and Cooling

HDPE pipes play a vital role in geothermal heating and cooling systems, where a heat-transfer liquid circulates through the ground to either absorb or release heat. Their durability, flexibility, and resistance to decomposition and oxidation make them well-suited for this demanding application. These properties ensure long-lasting performance in underground environments, making PE pipes a reliable choice for efficient and sustainable geothermal energy systems.

Comparison with Other Pipe Materials

PE pipes are one of the standard pipe materials used in modern construction, along with Copper, PVC, and Steel. Let’s discuss how PE pipes compare to each material in cost, durability, flexibility, and ease of installation.

Cost

- PE: The most cost-effective pipe material, especially in larger-diameter pipes.

- PVC: cheaper than copper and steel but may be slightly more expensive than PE pipes.

- Steel: Expensive due to material and labor costs. Requires cement lining internally, and corrosion-resistant coatings and electrical corrosion prevention systems externally. Subject to rust.

- Copper: The most expensive among these materials due to the high cost of copper.

Durability

- PE: Resistant to corrosion and are known for their longevity. Impact absorbing. Less subject to damage due to inadvertent dig-ups. More easily repaired than all other pipe types.

- PVC: Durable and resistant to corrosion and chemicals, but may not be as strong as steel or PE in specific applications. Increase in brittleness and decrease in impact resistance over time.

- Steel: Very durable and strong, suitable for higher-pressure applications. However, they can corrode over time if not adequately protected.

- Copper: Highly durable, has excellent corrosion resistance, and can last many years.

Flexibility

- PE: Very flexible and can be bent without specialized fittings.

- PVC: Rigid and less flexible than PE.

- Steel: Rigid, not flexible, and requires precise fittings and joints for installation.

- Copper: Relatively rigid but can be bent to some extent with the right tools.

Installation

- PE: lightweight and easy to handle, making them easy to install. It can be joined using various methods, such as heat fusion, etc. PE Pipe is fused above ground and pulled into the drilled hole with little surface construction required. It is so flexible and tough that it can be bent around curves and pulled through excavations 5 meters below the surface and still maintain its integrity for a 1-kilometer single, trenchless pull.

- PVC: Easy to install due to its lightweight nature and wide availability of various fittings.

- Steel: Heavy and more challenging to install than plastic pipes.

- Copper: Requires specialized fittings and soldering for installation, which can be more labor-intensive.

Limitations and Challenges of Using PE Pipes in Construction

While PE pipes are widely used in modern construction due to their advantages over other materials, you should still consider their limitations and challenges when using them.

Environmental effects, especially temperature, can be challenging when handling PE pipes. They are sensitive to sudden changes in temperature and may deform or become brittle in high or low temperatures. They have a high thermal contraction factor, which needs to be designed for when used for above-ground systems.

PE Pipe Market Size From 2024 To 2033

The PE pipe market was valued at around USD 19,495.99 million in 2024 and is expected to grow to USD 20,772.97 million by 2025. By 2033, the market is projected to reach USD 34,508.52 million, reflecting a CAGR of 6.55% between 2025 and 2033.

Several key factors are driving this growth. Advances in manufacturing, particularly improved extrusion processes, have boosted production efficiency by 15%. Sustainability is also a major trend, with a 10% rise in the use of recyclable PE pipes, aligning with the global push for eco-friendly solutions. Additionally, infrastructure expansion, especially in emerging markets, has led to a 20% increase in PE pipe demand, driven by urbanization and industrial growth. The Asia-Pacific region, particularly China and India, is seeing a 25% year-on-year rise in PE pipe consumption and is projected to hold over 35% of the global market share by 2030.

Reference: PE market size and analysis

Conclusion

For many years, above-ground applications have significantly benefited from the usage of PE pipes. As cities and industries move towards digitalization, there is an increasing opportunity for integrating smart technologies into PE pipes. This includes embedding sensors for monitoring water quality, pressure, and flow rates in real-time. The use of PE pipes equipped with such monitoring systems has seen an increase of 10% in demand, especially in urban areas aiming for smart city developments. Additionally, the growing focus on water conservation and efficient resource management provides a significant opportunity for PE pipes to be utilized in more advanced systems. This integration of technology not only enhances performance but also drives new applications in infrastructure.

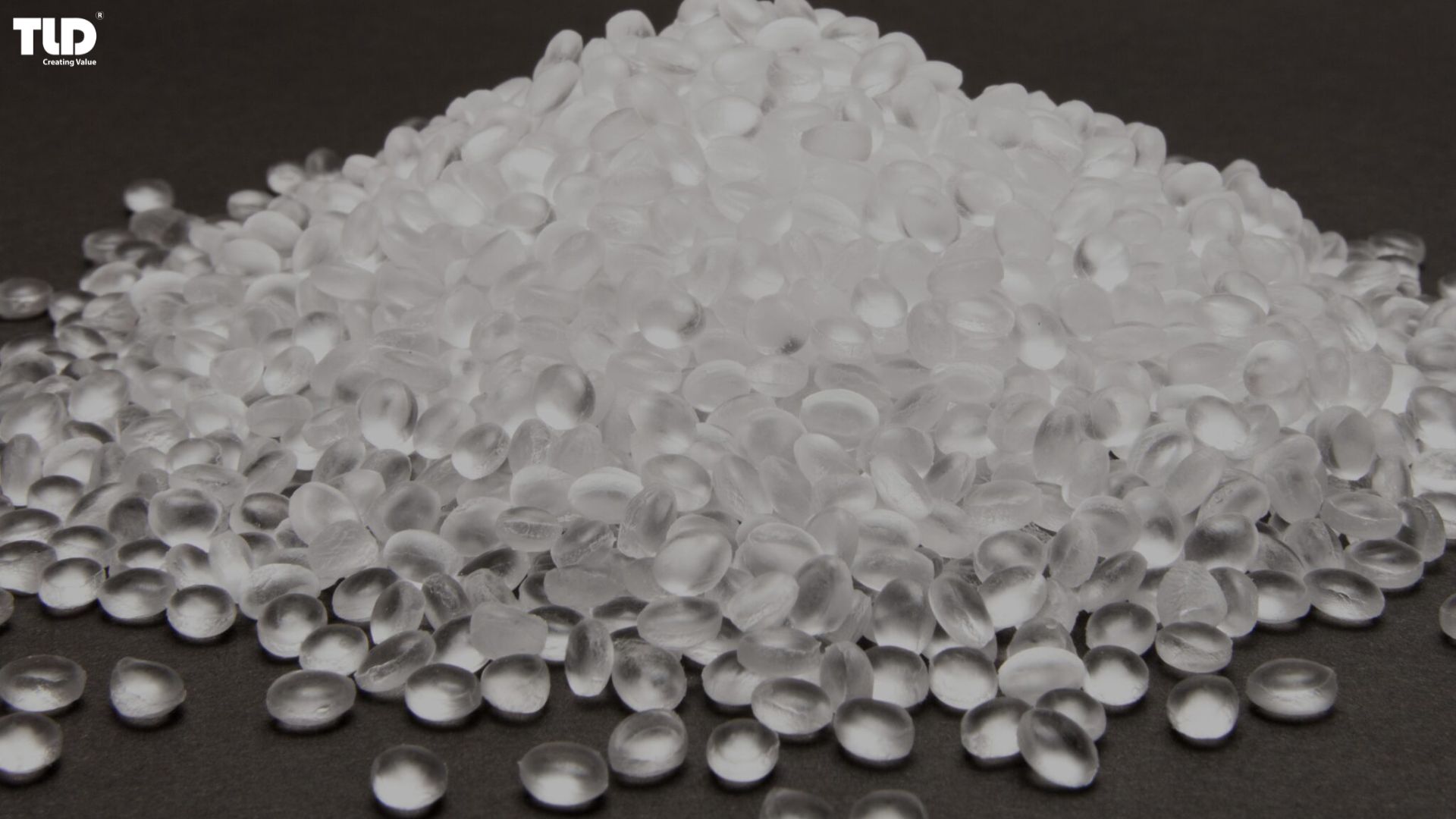

TLD Vietnam – Your Trusted Partner For Plastic Resins

One of the significant constraints faced by the PE pipe market is the fluctuation in the prices of PE resin, the primary raw material used in production. Over the past five years, prices have varied by around 8%. Since polyethylene is derived from petroleum-based feedstocks, the market is also sensitive to oil price shifts, causing unpredictability in production costs. This volatility makes it difficult for manufacturers to maintain stable pricing, potentially delaying large-scale infrastructure projects that require cost consistency.

TLD Vietnam is proud to be a prestigious supplier of plastic resin for your projects. Our focus is on providing the most efficient material solutions that balance quality and cost. We offer a wide range of plastic resins, including PE, PVC, PP, and PET. Additionally, we provide valuable insights into material knowledge, with information that is consistently updated to ensure accuracy and reliability.

At TLD Vietnam, we offer customized solutions tailored to meet the specific needs of our clients. With a strong global network spanning over 50 countries, we are committed to building enduring relationships through exceptional customer service. We are dedicated to promoting sustainable development, striving for progress in both business and environmental impact. TLD Vietnam is committed to excellence worldwide. Contact us today for the best quotation!