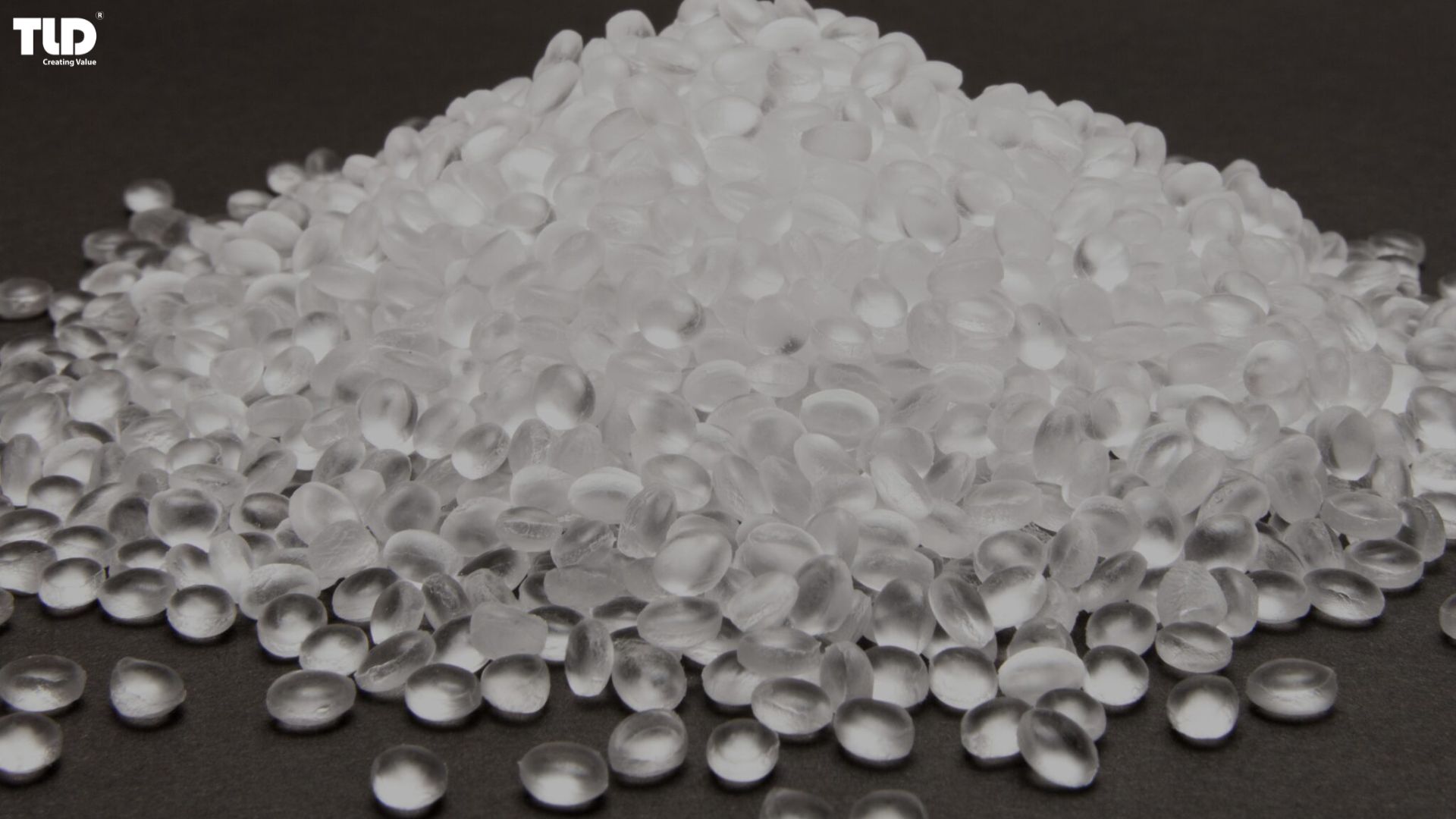

LLDPE, short for Linear Low-Density Polyethylene, is a type of plastic that has become increasingly popular in recent years. In this comprehensive blog post, TLD Vietnam will show a wide range of applications of LLDPE plastic. So, let’s get started!

The Basics Understanding LLDPE

LLDPE is a member of the polyethylene family, which is one of the most widely used plastics in the world. It is produced by the polymerization of ethylene, with the addition of small amounts of other alpha-olefins, such as butene, hexene, or octene. These additional monomers create a linear structure with short branches, resulting in a material that is stronger and more durable than traditional low-density polyethylene (LDPE).

One of the key features of LLDPE is its density, which typically ranges from 0.910 to 0.940 g/cm³. This lower density compared to other polyethylene grades, such as high-density polyethylene (HDPE), contributes to its unique properties and applications.

Major Benefits Of LLDPE

LLDPE offers a range of advantages that make it a popular choice in various industries. Let’s explore some of the key benefits of this versatile plastic:

Strength and Toughness

LLDPE is known for its excellent strength-to-density ratio, making it an ideal choice for applications that require durability and impact resistance. Its linear structure and short branches create a strong intermolecular force, resulting in a material that can withstand high stress and strain without breaking or deforming.

Flexibility and Softness

Despite its strength, LLDPE is also flexible and soft to the touch. This property makes it suitable for applications that require a balance of rigidity and pliability, such as packaging films and stretch wrap.

Clarity and Transparency

LLDPE has a high degree of clarity and transparency, which is particularly important for applications where visual appeal is a priority, such as packaging for consumer goods.

Chemical Resistance

LLDPE exhibits good resistance to a wide range of chemicals, including acids, bases, and solvents. This property makes it suitable for applications that involve exposure to harsh environments or chemicals.

Ease of Processing

LLDPE is relatively easy to process compared to other polyethylene grades, making it suitable for a variety of manufacturing techniques, such as extrusion, injection molding, and blow molding.

Key Applications Of LLDPE Plastic

LLDPE’s unique properties and advantages have made it a popular choice in various industries and applications. Here are some of the most common uses of LLDPE plastic:

Packaging

One of the largest applications of LLDPE plastic is in the packaging industry, where its flexibility, strength, and clarity make it an ideal material for various packaging solutions. It is widely used in the production of films, bags, and pouches for industries such as food, cosmetics, and pharmaceuticals. Common applications of LLDPE plastic in packaging also include stretch wrap and shrink wrap, which provide secure and protective covering for products during transportation and storage.

In addition, it is used in grocery and shopping bags, offering durability and lightweight convenience. Trash can liners made from LLDPE are valued for their resistance to punctures and tears, while bubble wrap and protective packaging help safeguard fragile items. Furthermore, pouches and sachets for snacks and personal care products benefit from LLDPE’s moisture resistance, ensuring product freshness and longevity.

Agriculture

LLDPE plastic is widely used in the agriculture industry due to its excellent resistance to weathering, making it ideal for outdoor applications. It is commonly used in the production of greenhouse films and mulch films, which help regulate temperature, retain moisture, and protect crops from harsh environmental conditions.

On the other hand, LLDPE irrigation pipes and tubing provide a durable and flexible solution for efficient water distribution in farming. The material is also utilized in silage bags and bunkers, ensuring the proper storage and preservation of animal feed by preventing moisture and oxygen infiltration. Furthermore, nursery pots and trays made from LLDPE offer durability and longevity, supporting plant growth and transportation in nurseries and greenhouses.

Automotive Components

LLDPE is widely used in the automotive industry due to its strength, flexibility, and resistance to chemicals and weathering. Its durability makes it an excellent material for fuel tanks and fluid reservoirs, ensuring safe storage and transport of essential automotive fluids.

Plus, LLDPE plastic is used in bumper fascias and trim, providing impact resistance and maintaining the vehicle’s aesthetic appeal. The material is also utilized in interior door panels and consoles, offering a lightweight yet sturdy solution for automotive interiors. Furthermore, underbody coatings and sealants made from LLDPE help protect vehicles from corrosion, moisture, and road debris, enhancing longevity and performance.

Toys and Sports Equipment

LLDPE is a popular material for toys and sports equipment due to its durability, flexibility, and resistance to impact and weathering. It is commonly used in playground equipment, providing a safe and sturdy structure for children’s outdoor activities.

Additionally, sporting goods such as kayaks and paddleboards benefit from LLDPE’s lightweight yet strong properties, ensuring long-lasting performance in various water conditions. The material is also widely utilized in outdoor furniture and decking, offering resistance to UV exposure and harsh weather while maintaining its structural integrity.

Furthermore, toys and games made from LLDPE are designed to be both durable and safe, making them ideal for children’s play and long-term use.

Toys and games

LLDPE plastic is widely used in the production of household and industrial products due to its strength, flexibility, and chemical resistance. In homes, it is commonly found in containers and lids for food storage, providing a safe and durable solution for preserving freshness.

Additionally, detergent bottles and caps made from LLDPE offer excellent resistance to chemicals, ensuring secure storage of cleaning products. The material is also used in various housewares and kitchen utensils, offering lightweight, durable, and easy-to-clean solutions for everyday use.

In industrial settings, LLDPE is utilized in drums and containers, ensuring the safe transport and storage of liquids and chemicals. Furthermore, pallets and crates for material handling benefit from LLDPE’s high impact resistance and durability.

Sustainability and LLDPE

As environmental concerns continue to grow, the sustainability of plastics has become an increasingly important topic. LLDPE, like other polyethylene plastics, is recyclable and can be reused in various applications, reducing waste and conserving natural resources.

Many manufacturers are also exploring the use of bio-based and recycled content in LLDPE production, further enhancing its sustainability profile. Bio-based LLDPE is produced using renewable resources, such as sugarcane or corn, while recycled LLDPE is made from post-consumer or post-industrial waste.

LLDPE Market Size and Forecast 2024 to 203

The global LLDPE market is expected to grow from USD 70.51 billion in 2024 to approximately USD 117.39 billion by 2034, with a CAGR of 5.23% over the forecast period. LLDPE is significantly more affordable than other polymers, making it an attractive option for cost-sensitive industries and applications. Its durability and resistance to environmental stress cracking further enhance its appeal.

Packaging remains the primary driver of LLDPE demand, thanks to its strength and moisture resistance, making it widely used in films for consumer goods, industrial, and food packaging. The Asia-Pacific region holds the largest market share, with e-commerce growth and rising consumer product consumption fueling the packaging industry’s expansion. Additionally, LLDPE is used in industrial applications such as pipes, liners, and geomembranes. Countries like China and India are seeing higher demand due to rapid industrialization and infrastructure growth. Market expansion is further supported by the development of enhanced LLDPE grades and advancements in production technologies, catering to evolving industry needs.

However, recycling LLDPE presents challenges, as it is often blended with other materials, making separation inefficient. Contaminants like food residues complicate the process, and distinguishing LLDPE from similar plastics in automated sorting systems can lead to inefficiencies and lower recycling rates. Additionally, the properties of recycled LLDPE can vary, with shorter polymer chains potentially reducing material strength, limiting its use in high-performance applications. Comparing recycling costs to new plastic production may reveal hidden expenses, discouraging investment in recycling infrastructure and technology within the LLDPE market.

Referrence: LLDPE Plastic market size

The Future Of LLDPE

As technology continues to advance, the future of LLDPE plastic looks promising, with ongoing research and innovation leading to new and improved grades with enhanced properties and expanded applications. One emerging trend is the development of ultra-low-density LLDPE (ULDPE), which offers even greater flexibility and softness, making it ideal for specialized applications.

Additionally, researchers are incorporating nanofillers and additives to enhance barrier properties and thermal stability, improving LLDPE’s performance in packaging and industrial uses. Another exciting development is the use of LLDPE in 3D printing and additive manufacturing, expanding its applications in custom and complex product designs.

Moreover, LLDPE is increasingly being adopted in the medical and healthcare industries, particularly for IV bags and tubing, due to its biocompatibility and chemical resistance. With continuous advancements, LLDPE is expected to play an even greater role in various industries, offering innovative, sustainable, and high-performance solutions.

Conclusion

As the world continues to grapple with environmental challenges, the sustainability of LLDPE is becoming increasingly important. The development of bio-based and recycled LLDPE plastic, as well as ongoing research into new and improved grades, suggests that LLDPE will continue to play a significant role in the future of plastics. With innovations in recycling and new product developments, the LLDPE plastic is expected to continue gaining popularity in global plastics industry.

TLD Vietnam – Your Trusted Partner For Premium Plastic Resins

TLD Vietnam is proud to be a reliable plastic supplier for your project. We always have the criterion of providing customers with the most optimal material solution in terms of both quality and cost. We provides a diverse range of plastic resin including PE resin, PVC resin, PP resin, PET resin for businesses worldwide. We take great pride in our robust global client network, spanning more than 50 countries. Our customer-centric approach and commitment to cultivating long-lasting relationships have established our reputation for delivering exceptional customer service.

TLD Vietnam constantly strives to promote sustainable development, aiming for progress not only in the business field but also in minimizing adverse environmental impacts. TLD Vietnam is steadfast in our commitment to excellence across the globe. Contact us now for the best quotation!